Could this be a new era for 3D printers? Major milestone reached as tungsten printing is now finally possible

Cracking and shape limits still restrict how far this process can go

Sign up for breaking news, reviews, opinion, top tech deals, and more.

You are now subscribed

Your newsletter sign-up was successful

- Tungsten carbide can now be printed without melting or ruining its strength

- A laser and heated wire soften metal just enough to bond layers

- Avoiding full melting reduces defects that previously blocked metal additive manufacturing

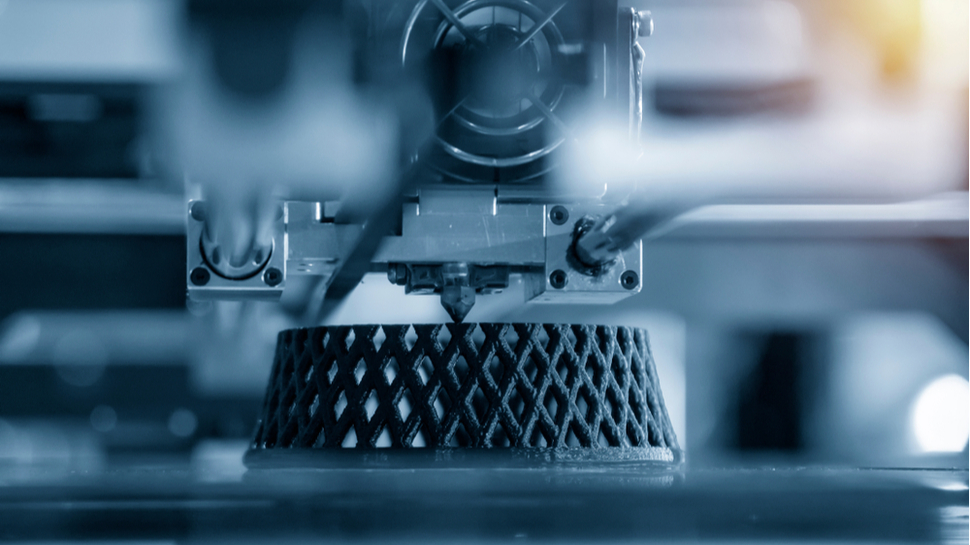

Most people are familiar with 3D printers making plastic parts, toys, or simple tools, but printing metal is far more difficult.

The reason is that metals require extremely high heat and react badly when heated and cooled too quickly.

However in a major breakthrough, scientists at Hiroshima University have now shown that tungsten carbide cobalt can now be 3D printed using a different method.

A different way to print without melting the metal

Instead of fully melting the metal, the process heats it just enough to soften it. This allows the material to bond layer by layer without losing its internal structure.

The method uses a laser and a heated wire to soften a solid carbide rod during printing.

A thin nickel alloy layer is also placed between printed layers to help them stick together more reliably.

Because the metal is not fully melted, the printed result avoids many of the defects seen in earlier attempts.

Sign up to the TechRadar Pro newsletter to get all the top news, opinion, features and guidance your business needs to succeed!

The researchers report that the final printed material reaches a hardness of over 1400HV, without introducing defects or decomposition.

This level of hardness is only slightly below materials like sapphire and diamond, which is unusual for 3D printed metal parts.

Tungsten carbide is widely used in cutting and construction tools, and it is one of the hardest engineering materials in use today.

These tools are usually made by shaping solid blocks of material, which creates a large amount of waste.

Being able to 3D print defect-free, industrial-grade carbides could reduce wasted material and allow parts to be made closer to their final shape.

The current process still struggles with cracking in some cases, and complex shapes are not yet easy to produce.

“The approach of forming metal materials by softening them rather than fully melting them is novel,” said Keita Marumoto, an assistant professor at Hiroshima University’s Graduate School of Advanced Science and Engineering.

“It has the potential to be applied not only to cemented carbides, which were the focus of this study, but also to other materials.”

Despite the progress, this work does not mean tungsten parts will soon be printed in everyday settings.

Metal printing remains slower, more expensive, and harder to control than plastic printing.

The researchers say further process refinements are needed to reduce cracking and allow more complex designs.

The idea of softening rather than melting metals appears promising, but its real-world value will depend on whether it can scale, repeat reliably, and work outside test environments.

Via Tom's Hardware

Follow TechRadar on Google News and add us as a preferred source to get our expert news, reviews, and opinion in your feeds. Make sure to click the Follow button!

And of course you can also follow TechRadar on TikTok for news, reviews, unboxings in video form, and get regular updates from us on WhatsApp too.

Efosa has been writing about technology for over 7 years, initially driven by curiosity but now fueled by a strong passion for the field. He holds both a Master's and a PhD in sciences, which provided him with a solid foundation in analytical thinking.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.